for The Sill

Starting at the fulfillment plant, we observed the process of putting together orders and assessed the utility of each material component. We composed a natural material palette to replace the existing packaging components that stood at odds with environmental strategies, and measurably reduced the amount of material required to package products.

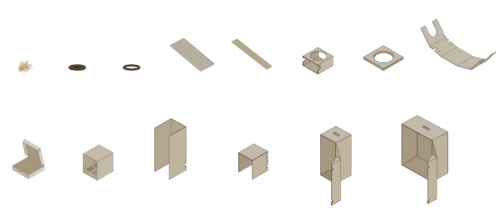

Natural fibers in various forms made up the palette for a new construction system.

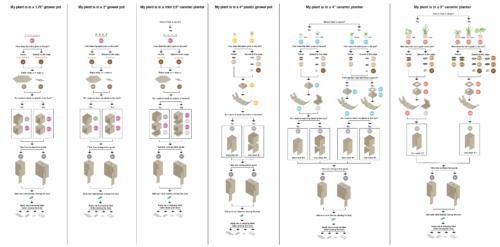

The key challenge of designing The Sill’s new packaging system stood in accommodating for the high SKU count of planters – all varying in height and diameter – as well as the complexity of orders: one plant, two plants, three cacti, a bag of soil – the combinations could be endless.

Analyzing most common orders to give the system a focus, and understanding that our packaging would need to primarily accommodate for high-volume SKUs before making exceptions for more “exotic” orders, we developed a system whereby a subunit registered with a feature in the shipper. Intelligently securing the plants and soil in place to withstand the hardships of mail travel. And allowing for customized components to be made in smaller quantities.

A diagram view of the order and SKU variety accommodated by the new system.

Because plants can be challenging to handle, we designed tools and diagrams for the team in charge of packaging the plants. Creating more predictable outcomes and a standard for consistent packaging.

Our packaging redesign for The Sill was a three-fold success in terms of scalability, consumer satisfaction and sustainability KPIs. Resulting in a more operationally efficient system, the new unboxing experience also sees consumers joyfully greeted by their new, healthy houseplants, while on the back end, all packaging components fit into a single recycling stream. Goodbye bubble wrap, hello plant!

Launched in 2012 by Eliza Blank, The Sill is one of the most well-loved online houseplant retailers.

As a scaling DTC start-up, The Sill worked with ATLASON to solve a few challenges that were getting in the way of growth: on one hand, the company was experiencing product returns due to plants getting damaged on their way to consumers’ homes, while on the other, orders took too long to be fulfilled because of the defective packaging system. Finally, The Sill saw an opportunity to elevate and make more sustainable the overall unboxing experience in order to align with brand ideals and consumer expectations.